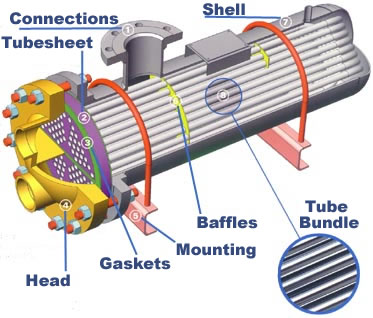

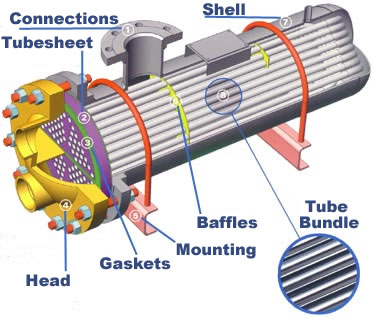

Did you know that the shell and tube heat exchangers are the most common types of heat exchanger pipe, used across various industries?

USEL Tubular Division are suppliers of heat exchanger tubes and are proud to deliver these to a wide range of industries, including the petrochemical industry, oil refinery, chemical and pharmaceutical industries. They aim to meet all high-quality standards, ensuring that heat transfer is efficient!

Any heat exchanger tubes suppliers will provide a wide range of designs to help you choose the right heat exchanger tube, take Tube Supply for instance! The shell and tube heat exchanger can be moulded to suit your specific requirements, find out how here!

First of all, you’ll need to select the most suitable turbulence flow (which will be dependent on temperature and pressure).

The water will flow through the tube side and air will flow through the shell side ensuring that the 2 materials are kept separate, maintaining their unique temperatures. The shell and heat exchanger tube is especially flexible and can be tailored to suit your needs specifically.

You’ll need to define the materials.

State what the material is. Is it stainless steel? Perhaps it’s water? Be specific. The walls of the heat exchanger tubes are likely to be made from steel but make sure this is evident in your model.

Assign flow boundaries.

Inlet and outlet conditions will be added to the flow of water and air but will allow the fluids to flow easily- keep this simple on the model.

Add symmetry.

The flow needs to be symmetrical for the best results to be achieved. The “walls” are the interior boundaries for the heat exchanger pipe.

Make sure you define the heat transfer.

For this, you’ll have to identify the temperature at the inlet and also the outflow from the outlets. The heat transfer needs to be defined in order to create a reliable model.

Don’t forget temperature boundaries.

The temperature boundaries are to be considered when modelling a shell and tube heat exchanger if you want to model the shell and tube heat exchanger effectively!

Evaluate the transfer of heat.

You’ll need to identify whether the air pressure has dropped. This will require modelling coupling operators.

To model a shell and heat exchanger pipe, you simply need to remember to be accurate and to ensure that the heat exchanger retains the same high-quality standards.

USEL Tubular Division has a solution for transferring heat efficiently, so don’t hesitate to get in touch with them today! They will be more than willing to provide you with any extra information that you require for modelling a shell and heat exchanger tube.

Click here to make an enquiry!