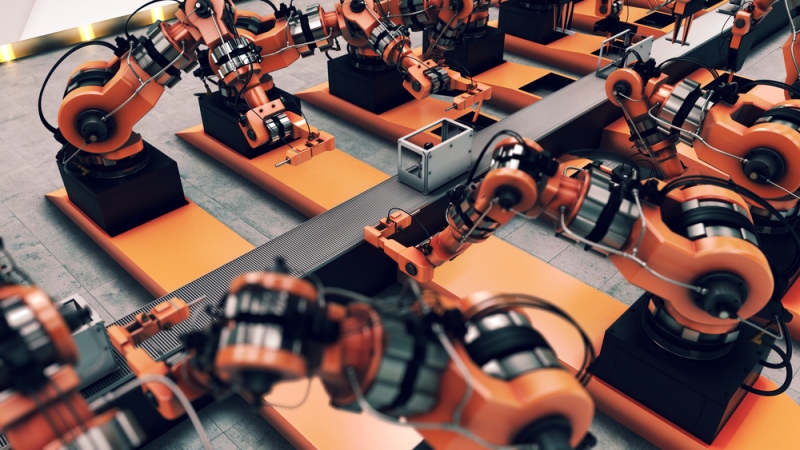

While the average person may imagine that most factories and plants in their city will indeed be almost completely fitted with all manner of fancy machines performing the lion’s share of the work, automation is actually sorely missing in many sectors.

If you own a factory or plant, and feel like it is sorely missing in some automation aspect, then you want to look to a leading name in automation services such as Trimantec for your modernized.

What is Automation in Today’s World?

The modern world of science and technology has brought an abundance of development in industry. Levels of production that were once unimaginable are now being completed every single hour around the world.

We have the brilliant minds that continue to develop the wonderful machines that tirelessly strive to support the industrial sector and economy. There are no sectors that will not benefit from the right level of machinery being installed.

Today, the avenues that benefit the best from automation are endless. They include processes such as dispensing, cutting, welding, material handling, packing, palletizing, hazardous waste handling, smelting and the handling of superheated materials and substances.

What Automation Brings to you and your Employee’s Lives

Every factor of your production and business runnings will begin improving and running more productively and smoother, not to mention with a new grade of safety. You will also begin to see your profitability soar.

A Reduction in Production Costs: While the actual purchase and installation of automated machinery might be a moderate expense, you will not believe how incredible the rate of investment will be.

Maximizing Floor Space: Space is limited in most factories, and those in charge of making the most out of such areas will benefit infinitely when automated machinery can do a wide variety of tasks in a smaller space than was previously being achieved.

A Precise Resource Usage: Robots can be programmed to utilize the exact amount of raw materials that you instruct them to. There is minimal wastage with such advanced levels of precision and artificial intelligence.

Reduced Waste Levels: This point ties into the previous one: with a more precise resource usage comes a far lessened and controlled level of waste production. You can also employ automated robots to handle waste disposal in the safest and most efficient manner possible.

An Increased Level of Reliability and Quality: Automation results in an infinitely repeatable work schedule that is continually completed quickly and with absolute finesse. You are assured the exact same quality results every single time you run a task.

As for repairs, today’s automated machinery barely ever needs repairing or part replacement, being designed to be themselves as unstoppable as their perfected working schedules. You should not expect costly repair orders.

Staying Ahead of the Competition: Business owners will most likely have competitors. Nothing puts you ahead of the game like automation, and nothing will boost your position in the charts and graphs like the most appropriate upgrades to your factories or plants.